对于HFO-1234yf系统,必须进行制冷剂识别。只有当

制冷剂高于98%,允许回收。

在开始回收过程之前,检查并清空旧油罐。

回收过程从车辆空调系统中排出制冷剂,直到达到真空。在此期间

在这一过程中,制冷剂从任何水分、油和外来颗粒中得到净化。然后,处理后的制冷剂

存放在机器的内部储液罐中,可重复使用。如果在此过程中回收了任何机油,

油将被排放到旧油船中。次恢复完成后,机器将

暂停3分钟,检查车辆空调系统中是否有制冷剂残留。恢复将再次开始

如果在3分钟暂停期间压力升高,则自动执行。恢复完成后,机器将

显示并打印回收的制冷剂和机油的总量(如果有)。

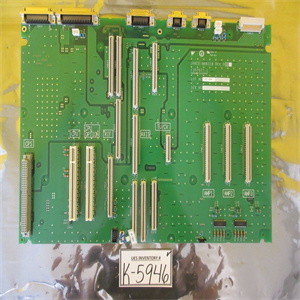

JANCD-MSV01B-485233

For the HFO-1234yf system, refrigerant identification is necessarily processed. Only when the purity of refrigerant is above 98% the recovery is allowed. Check and empty the used oil vessel before the recovery process is initiated. The recovery process removes refrigerant from the vehicle A/C system until a vacuum is reached. During this process, the refrigerant is purified from any moisture, oil, and foreign particles. The processed refrigerant is then stored in the internal storage cylinder of the machine, ready for re-use. If any oil is recovered during this process, the oil will be discharged into the used oil vessel. After the first recovery has been completed, the machine will pause for 3 minutes, to check if there is any refrigerant left in the vehicle A/C system. Recovery will start again automatically if there is a pressure rise during the 3-minute pause. At the completion of recovery, the machine will display and print the total amount of refrigerant recovered and oil if any.

客服1

客服1